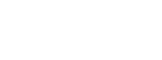

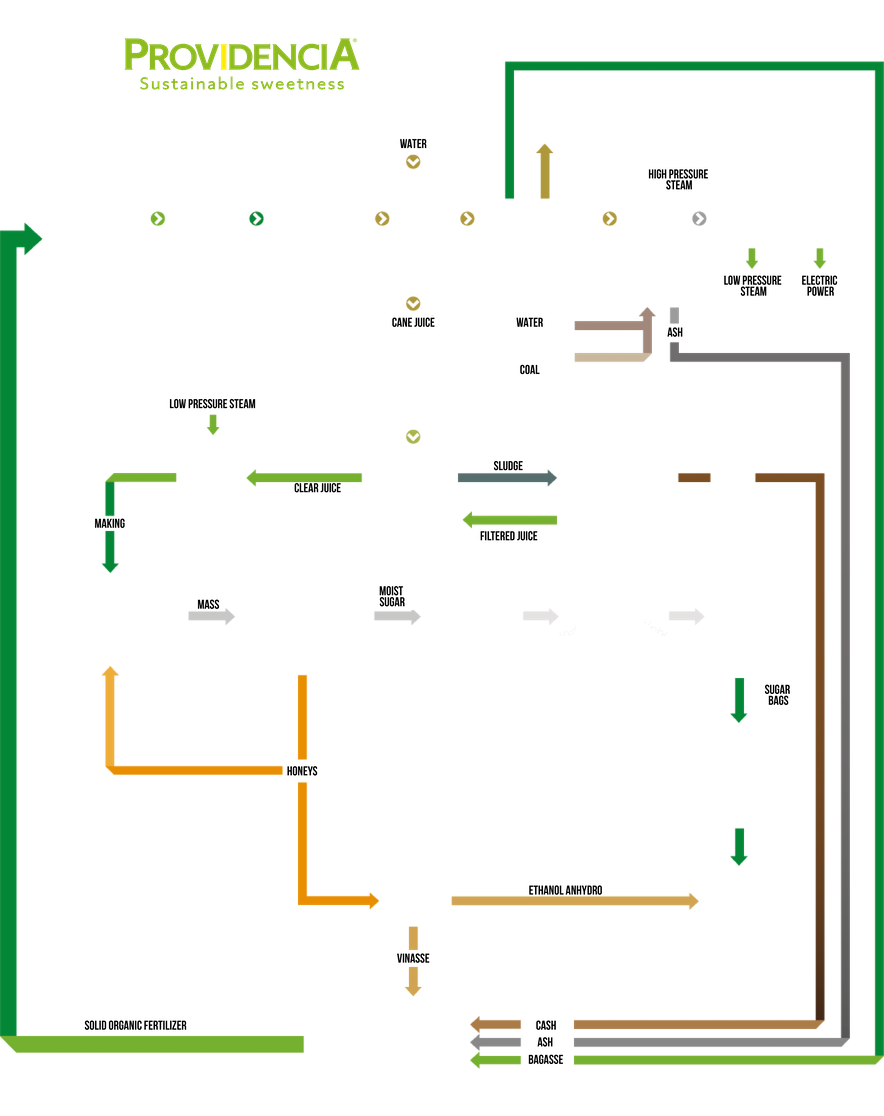

Sugar cane must go through to physicochemical and biological processes to be transformed into sugar, alcohol and energy.

Let’s see how is done:

Process of fractioning dry sugar in different presentations according to the customer’s needs.

Juice purification process by means of sludge or impurities sedimentation. Flocculent is added to the hot juice and sent to the clarifiers, where the separation of insoluble solids is achieved.

Temperature increase of the cane juice (from room temperature to 102°C) using steam and heating equipment to accelerate the separation of insoluble solids.

Transformation of the steam energy generated in boilers, into electrical energy, using turbo-generators. It supplies the needs of the plant and allows the sale of surplus power to the public network.

Process in which the sugar cane produced in the field is transported to the sugar production Factory.

Production of mineral organic fertilizer from by-products of sugar and anhydrous alcohol production.

Storage of the different sugar presentations under conditions of controlled temperature and humidity.

This plant sends completely softened water to the boilers and the cooling towers. A portion of the treated water in this plant is used as dilution water in the fermentation. Thus, the process does not generate any liquid effluent.

Process of removing excess moisture of sugar by placing it in direct contact with dry and hot air in rotating drying equipment

Process of separating sugar crystals and molasses using centrifuge machines.

Process of sugar crystals formation through water evaporation under controlled conditions of temperature and concentration in vacuum equipment.

The process of removing water from cane juice to transform it into cane syrup, using multi-stage evaporation equipment. The generated steams are used in the heating process.

Recovery process of the sludge sucrose using vacuum filters, adding hot water and bagasse.

Transformation process of steam treated water under high pressure and temperature for thermal expansion processes in steam turbines for producing electricity and thermal sub-processes of the Factory. It uses sugar cane bagasse as a renewable fuell, by-product of the cane milling.

Extraction process of the cane juice using mills with action of mechanical compression and using maceration with hot water or juice.

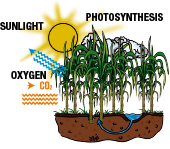

The Harvest is responsible for carrying out the programming and execution of the work of cutting, raising and transportation, meeting the standards of quality, timeliness, environmental legislation and low cost.

It includes all the manual and mechanized agricultural works required by the sugarcane crops, including the design, adaptation, preparation, planting and raising of the plantations until their harvest.

Browse and interact with the infographic

Browse and interact with the infographic

Countryside

Harvesting

Sugarcane

transport

Milling

BAGASSE FOR PAPPER

BAGASSE

HIGH PRESSURE

STEAM

Steam

generation

LOW PRESSURE

STEAM

ELECTRIC

POWER

Power

generation

JUICE

WARMING

COAL

WATER

JUICE

EVAPORATION

Juice

clarification

Sludge filtration

Cachaza

Crystallization

Centrifugation

Drying

Sugar

Packaging

Finished

product warehouse

Ethanol

production

Customers

Composting